Hot nozzle

Filters

Color

Clear

roll up

Density

Clear

roll up

Effect

Clear

roll up

4 bought

NEW

ID: 21540

671 ֏

6 bought

NEW

ID: 21537

671 ֏

2 bought

NEW

ID: 21539

671 ֏

6623 bought

ID: 3678

1 253 ֏

3318 bought

ID: 3688

2 237 ֏

2025 bought

ID: 12595

637 ֏

-5%

2293 bought

ID: 1863

1 487 ֏

-5%

2010 bought

ID: 12194

1 275 ֏

-5%

1473 bought

ID: 11773

850 ֏

-5%

210 bought

ID: 11600

1 331 ֏

-15%

163 bought

ID: 11602

1 331 ֏

-15%

224 bought

ID: 11598

1 253 ֏

-20%

206 bought

ID: 11596

1 331 ֏

-15%

139 bought

ID: 11604

1 331 ֏

-15%

71 bought

ID: 13093

228 ֏

-15%

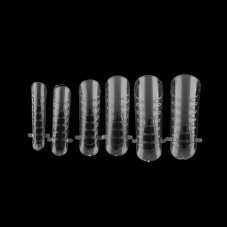

A hot nozzle is a crucial component in many modern manufacturing processes, particularly in the production of plastic products. Essentially, a hot nozzle is a heating element that is integrated into a machine to melt plastic pellets or granules, which are then shaped into a specific form. Hot nozzles are commonly used in injection molding machines, which produce large quantities of plastic products. Plastic pellets or granules are fed into the machine, melted, and then forced through a nozzle into a mold cavity. The material then cools and solidifies, forming the final product. One of the key advantages of using a hot nozzle is that it allows for precise control over the temperature of the plastic material as it is being shaped. This is important because different types of plastics have different melting points, and the temperature must be carefully controlled to avoid damaging the material or producing an inferior product. In addition, the use of a hot nozzle can help to reduce cycle times, as it allows for faster melting and distribution of the plastic material. Hot nozzles come in a variety of shapes and sizes, depending on the specific requirements of the manufacturing process. For example, a nozzle for a milling cutter might have a flat or rounded end, whereas a nozzle for nail extensions might be narrower and more pointed. Technicians who work with hot nozzles must be trained to understand the different types and to use them correctly. Overall, the use of a hot nozzle can significantly improve the efficiency and quality of a manufacturing process. By allowing for precise temperature control and faster melting times, companies can produce high-quality products more quickly and cost-effectively than ever before.