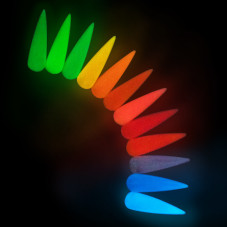

Flame shape

Filters

Color

Clear

roll up

Density

Clear

roll up

Effect

Clear

roll up

229 bought

NEW

ID: 15379

105 ֏

-20%

215 bought

NEW

ID: 15380

105 ֏

-20%

59 bought

NEW

ID: 17365

105 ֏

-20%

335 bought

NEW

ID: 16843

105 ֏

-20%

102 bought

NEW

ID: 16010

105 ֏

-20%

6674 bought

ID: 3678

984 ֏

-20%

3340 bought

ID: 3688

1 757 ֏

-20%

3344 bought

ID: 2071

1 054 ֏

-20%

2027 bought

ID: 12595

527 ֏

-20%

1567 bought

ID: 1994

984 ֏

-20%

2319 bought

ID: 1863

1 230 ֏

-20%

2019 bought

ID: 12194

1 054 ֏

-20%

1488 bought

ID: 11773

703 ֏

-20%

1753 bought

ID: 12137

703 ֏

-20%

210 bought

ID: 11600

1 306 ֏

-15%

191 bought

ID: 11951

878 ֏

-20%

163 bought

ID: 11602

1 306 ֏

-15%

225 bought

ID: 11598

1 230 ֏

-20%

206 bought

ID: 11596

1 306 ֏

-15%

139 bought

ID: 11604

1 306 ֏

-15%

Flame shape is an important aspect of many industrial processes, whether it is the shape of a welding arc, a cutting torch or a furnace flame, it impacts the quality and efficiency of the process. Understanding the factors that affect the shape of the flame is crucial for optimizing these processes. Diamond head milling cutters are widely used in various industries for cutting and shaping hard materials. The flame shape plays a significant role in the cutting process. The correct flame shape can minimize damage and wear to the milling cutter, increasing its lifespan and reducing maintenance cost. The flame should be focused and directed towards the cutting edge, providing efficient cutting. Nozzles for milling cutters also play a crucial role in the flame shape, as they determine the angle and intensity of the flame. The right nozzle can produce a narrow, focused flame that is ideal for precise cutting, while a broader flame can be beneficial for rough cuts. Nail extensions have gained popularity in recent years, and it is essential to use the correct flame shape when applying them. The flame should be held at a precise angle and distance from the nail to prevent damage to the natural nail and achieve the desired shape of the extension. Technics, or the use of specific techniques, is also crucial in shaping the flame. For example, in welding, the correct technique can help achieve a stable and consistent flame shape, which is required for high-quality welds. Similarly, in furnace operation, proper temperature control and airflow management can help achieve the desired flame shape, ensuring efficient and effective operation. In conclusion, understanding flame shape is crucial for any industrial process that involves heat and flames. It affects the quality and efficiency of the process, reduces wear and damage, and helps achieve the desired results. Choosing the right nozzle, using the correct technique, and managing temperature and airflow can significantly impact the flame shape, optimizing the process and improving the outcomes.